Sparks

| The pace quickens to a frenzy as Labor Day approaches. The mackerel

are schooling, lobster catchers are coming in freighted, web worms

are festooning the trees, gardeners are trying to give away tomatoes,

and the Summer Complaint grows feverish. When I was a Summer Person

at Owls Head this was the saddest week of the year. The thought

of going back to school in the burbs was enough to make you cry.

Even the dog drooped. |

Web Worms

|

Beginning Side Decks

|

This year I'm chasing my tail in the dooryard, trying to inch

this barge closer to the water. Even visitors get dragooned. Yesterday

Susan, my cousin from England, put a second coat of deck paint

on the beast. Now it's down to frigging with the rigging. And

I've got tunnel vision. There's a time in each creative process

when everything else disappears. You are riveted on the one task,

and any distraction makes you fume. I've stopped drawing, painting,

writing, reading, musing, mowing the lawn. |

| Not that the final product is envisioned in detail. All the postponed

decisions are now knocking. The shape of the leeboards, and where

to hang them. The final dimensions of the spars, and how to hoist

them. Rudder hinges and a steering hub. I've raided all the hardware

stores, marine and otherwise, from Portland to Rockland, for fittings

and foofraws. I can report that just in time inventory keeping

has captured the marine supply business. Try and get mast hoops

in August. Hah. They're back ordered until March. |

After Coamings

|

|

But I'm marching under orders. Guess I'll lace that sail to the

mast and use parrels (wooden beads on the loops). Keep it simple.

Use the materials at hand. After juggling all the possibilities,

it comes around to the down and dirty. And I've had some just

in time advisors help resolve my conundra.

|

| Lee Huston breezed into the boat yard a few weeks back, just when

I was despairing about gaff rigs, centers of resistance, and the

details of lee boards. Lee has built upwards of 40 traditional

wooden boats, and followed rumors of a scow abuilding to Brooklyn

Heights. He not only answered all my questions, he returned the

next day with a stack of texts all indexed with post-its, covering

the topics in detail. He also preached the simple solutions, and

cooled my broth. |

|

|

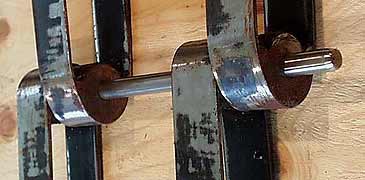

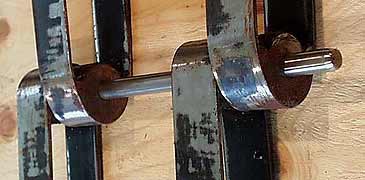

David's design for rudder hinges required four massive bearings,

bored and chamfered by a machinist, so I rooted into another layer

of the local landscape, looking for a lathe man. We used to brag

that more patents had been issued to Mainers than to anyone else,

the result of long winters and a large bump of Yankee ingenuity.

Scratch a local and your fingernails were full of filings. Now

it seems that all the little job shops in this tinkerer's paradise

have gone south. Or west. Or somewhere else. So-and-so used to,

but he sold his milling machine. |

| I went to Art Boulay for advice. He does small engine repair and

is a trove of mechanical info. Of course he wanted to know what

I was cogitating, and maybe it could be done this way, and I could

get the steel at T.W.Dick, and when I asked who might do the turning,

Art said, "Guess I could." And he collared and fitted a shaft

on my steering wheel, too. And filled my head with lore. When

you consider the vast accumulation of technical knowledge an artisan

stores away in a lifetime, the death of a craftsman seems like

a bad joke. The demise of the local job shop marks another passage

on the road away from individual understanding and tangible mastery. |

|

Rudder bearings

Ouch

|

No shortage of that at Liberty Salvage, though. McLaughlin got

hooked on steel early and has kept honed ever since. He's the

only person to graduate from Yale with a degree in welding and

a minor in stagecraft. Did a hitch in the Signal Corps where his

speciality was standing up towers, and spudded down at the old

cannery in Liberty in 1971. His passions are steel fabrication

and moving heavy things.. and beautiful young women. A very romantic

guy, who used to cruise the coast in a handmade road warrior vehicle,

David 's most recent love wagon was a hot little Miata, until

he got distracted by a lady companion, and pranged it. Now he's

back to flatbeds and crane trucks. |

| One Monday morning I scored some steel at T.W.Dick, swung by Whitefield

to pick up Torbert, and climbed the country to Liberty. David's

been renovating the cannery and adding to his collections for

28 years, and his whole compound is a grand work in progress.

David says that one characteristic of pack rats is they constantly

reorganize their troves, and he's presently dragging all the iron

piles out of the courtyard, into his back lot. Canning tanks and

metal wheels. International trucks and assorted ironmongery. And

granite, of course. He's framing everything with massive hunks

of ledge. |

Tanks

|

Liberty Salvage

|

And the buildings soar up like Italian street scenes. Whenever

David needs more space he cuts a room off at the floorline with

a chainsaw, and jacks it up a story. His "studio" building, about

the size of your average factory, has just such a breezeway gaping,

and David dreams about an artist in residence who would help close

in and fill the space with creativity. |

The inside of his workshop is all gloom and rust and concrete

and racks of tools. The jet roar of acetylene, the rasp of grinders,

streams of sparks, the clamor of hammered iron. Jim and I admired

David's jigs and fittings while he made bar stock red hot, and

bent it round the rudder bearings. Fabricating the hardware for

the ark took all day, and I drove Jim home in the noontime, then

went back to grinding and drilling and reaming and watching the

arcing flash.

|

|

Wheels

|

McLaughlin is an artist with a torch and arc, and he wasn't about

to half do it. The bowsprit end, rudder hinges, and tabernacle

shaped up to be bold statements of rugged utility, in perfect

harmony with the traditional workboat lines of this scow. And

David kept up a running commentary on the nature of the work.

Teaching me about steel and cutting and welding, and the process.

Each step hinged on an aphorism. |

Tabernacle up

|

"When you make a mistake, redo it at half speed."

"Perfect it with a chisel and file." |

Tabernacle Down

|

| He shared a craftsman's mutterings, as the day burned away black-handed

and sooty-faced. We didn't finish until 9:30 in the PM, and fumbled

up his unlit stairs to an exhausted feed of pilot crackers and

kippers in hot sauce, with black tea. Might have figured us for

a pair of Scotsmen. I rolled home in Ebba, a load of splendid

ironwork clanking in the bed. Thinking about the nature of art. |

Chains

|

Hanging

|

Our painter friends turn themselves inside out onto canvas, then

hold it up for the world to see. The work is about the doing,

but the world only talks about the showing. The art business and

the artist's life are wrenched apart. Small wonder the "fine"

arts in America are so alienated. David has done his share of

gallery sculpture, but that abstracted universe can't scratch

his itch for massive metallurgy. Merely contemplative objects

don't carry enough load, but pure utility can ring hollow, too.

McLaughlin fuses his esthetic sensibility with practicality, and

makes necessary things of profound beauty. His informed esthetic,

once commonplace, has melted in a plastic age. |

Spending a day with a fellow artisan who isn't too proud to weld

a tabernacle, and who cites Giacometti while laying down a bead,

refreshes my joy in the work. Isn't it our responsibility to bring

beauty into a practical world? To recognize the abstract qualities

in every object. To launch scows among the Clorox bottles?

|

Masks

|

Oilers

|

And we are thinking about launching. All the details may not be

done by a given deadline, but it grows time to make a splash.

My ambition is to have all the fittings on the hull by next weekend,

and slide her down the ramp on Sunday the 19th. You are all welcome

for the event. Around 2PM. |

| The matter of naming has amused us, but it was resolved by the

beast herself. As soon as I fastened the last foredeck plank,

set the vent scoops into it, and stood back, it was obvious. TOAD,

indeed. Come join us break a bottle on the Millennium Toad. |

Toad!

|